TECHNOLOGICAL ASPECTS OF COLD STORAGE PROJECT

To store a product at a required temperature the refrigeration system within a cold

storage plant work on two principles, they are:

Vapor absorption system in the cold storage project: This system is economical and can compensate for the initial investment. It helps conserve energy and operational cost. It has some limitations in storing items or produce below 10˚C.

Vapor compression system in the cold storage project: This is again available in three different types depending on the temperature required in the storage rooms. The diffuser type system is used when the height of the storage room is low. The bunker type system is used when the storage room height is above 11.5 m. The fin coil type system is used for room height above 5.4 m and this is an energy efficient system,but 5% more costly than the other two system types.

The refrigerant is a material which allows the cooling process to happen, i.e. it takes up heat byevaporation (at a lower temperature and pressure) and gives up the heat by condensation (higher temperature and pressure). Freon as a refrigerant is banned and ammonia is being presently used as a refrigerant for cold storages.

Compressors with high speed reciprocation and atmospheric condensers are used because they are easy to maintain, cost less and are energy efficient.

Equipment for the cold storage should be properly selected such that it can handle heat loadsand heavy use during the summer. The capacity of a cold storage to tolerate the heat loaddepends on its design and therefore the following factors should be considered Fan load.

- Light load.

- Age of the equipment.

- Product load.

- Heat from the stored produce.

- Load of the fresh air charge.

- Heat from the ceiling, walls, floors etc.

There should be proper insulation of the cold storage area and the commonly used material for insulation purpose is thermocouple or poly urethane fiber (PUF). Each part of the cold storage should be insulated with two layers of the material. In areas exposed to the heat of the sun need to be insulated with a material thickness of 100 mm, whereas for other areas 80 mm thick insulation material is enough.

If there is no availability of soft water near the cold storage area, then it is important to incorporate a water softening plant nearby.

A 10 Metric tonne capacity of cold storage has an electric load of 5.9KW and the power supply requirement is around 230 volts/3 phase /50 Hz.

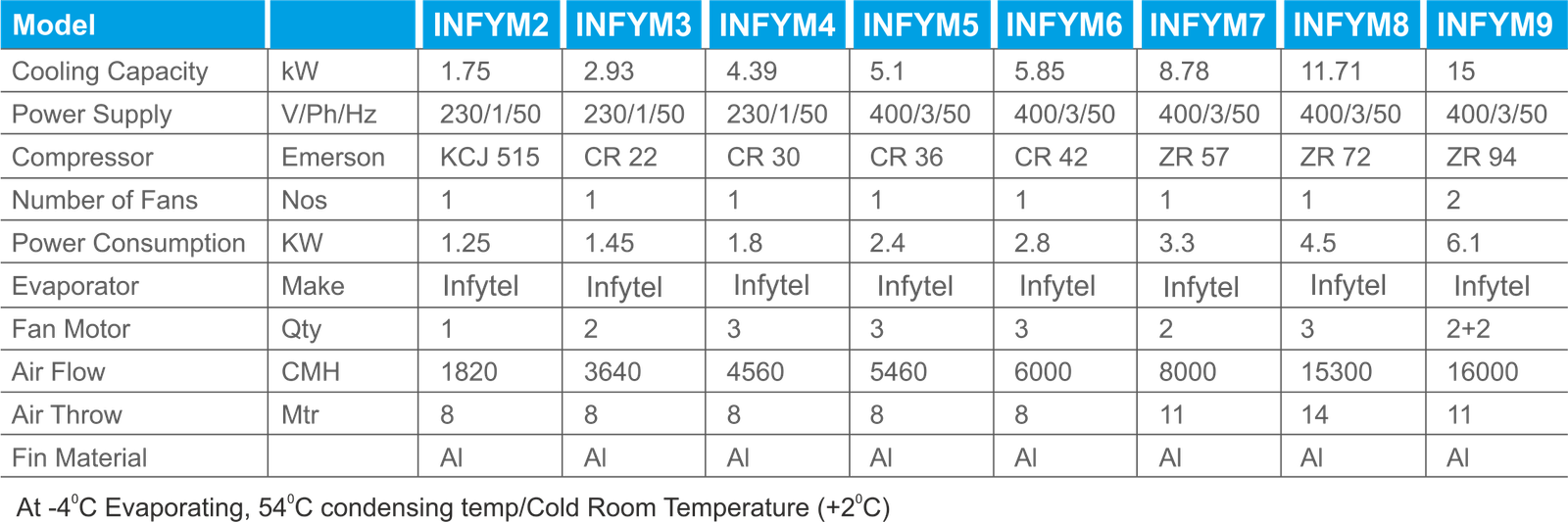

Medium Temperature Refrigeration System

Type of Construction:

Type of Construction:

Heavy structure with pre fabricated sandwich panels with lock on all sides all panels fit together by cam lock,so container becoms air tight fit.

Wall Thickness:

Insulated wall thickness 50mm(Small Vechicle,100mm(Mini truck)&125mm(Heavy Loading Truck).

Surface Material:

Outside pre coated Gl aheet skin thickness 0.8mm or s.s grade 304,thickness 0.5mm inside pre coated Gl sheet skin thickness 0.8mm or 5.5 grade 304 t5hickness 0.5mm.

Type of Floor:

We are providing outside pre coated Gl sheet,Thickness 0.8mm & inside 9mm or 19mm or marine ply with FPR layer for water proof & top material as per below details.

Option1 : Aluminium T profile for easy moving & air rotation.

Option2: aluminium Checkered plate.

Option3 :5.5 202 rectangle pipe structure for better easy moving & air rotation.

Door:

Single loft door for small vehicle 7 double left door for mini and heavy loading truck.